Failure to adhere to these firearm safety rules, and applying your safe behaviour, is a serious accident just waiting to happen. And it will. With dire, serious life changing consequences for the worse. You have been warned.

DESCRIPTIONS ...

DESCRIPTIONS ...

There are essentially two types of barrels for long guns, smoothbores (also called muskets or fowlers) and rifles.

Smoothbore barrels are simple tubes in various gauges/calibers, that can be loaded with shot (pellets, as with a shotgun), or with one or more pure lead balls.

Rifled barrels have spiral grooves cut inside their tubes so that a loaded ball will have spin imparted to it by the lands (or ridges) created by those grooves, and that drastically increases accuracy, particularly at longer distances. Rifles were created to only fire pure lead balls or conical bullets.

While there are other, older types of traditional muzzleloader ignition systems, there are essentially two types of ignition systems within the focus of this document - the 18th century flintlock and the 19th century percussion caplock.

The flintlock is recognized as a 17th century French invention which quickly was adopted by European military and found its way throughout the known world, particularly the New World and Colonial America. Flintlock long guns (smoothbores and rifles) were the weapon of choice for all of the 18th century and a good part of the 19th century as well.

The flintlock consists of a hammer (or cock) that holds a piece of flint rock (chert, agate, jasper, and many other rock types). When the trigger is pulled the sharp flint strikes the long eared frizzen and cuts off bits of metal from the frizzen, creating red-hot sparks of the frizzen's metal that ignite the black powder in the lock's pan. The exploding pan powder results in radiant heat, some of which travels into the barrel's touch hole, thus igniting the main charge of black powder in the barrel, firing out the patched pure lead ball. This is a flintlock ...

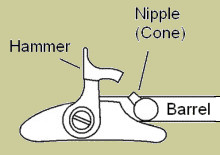

The caplock

The caplock percussion system was developed by Reverend Alexander John Forsyth and patented in 1807. It consists of a hammer that when released lands on a percussion cap placed over a nipple (or cone). The flame of the cap's explosion goes down the nipple and ignites the barrel's main powder charge, firing out the lead ball or bullet or lead shot. This is a caplock ...

COMPONENTS ...

COMPONENTS ...

While caplock percussion long guns will appear to be easier to load and care for, with a bit more knowledge and practice, flintlock long guns can be just as easy and reliable to use. A flintlock long gun is the basis of our American roots and heritage, and was the tool used for Colonial family sustenance, protection ... and freedom, for more than 200 years. An interesting side note - flintlock rifles and black powder are still being used as a primary means to provide sustenance today in some undeveloped countries around the world, even as we are now entering into the 21st century.

Long gun calibers can range from .25 or smaller to .78 and larger.

As of this writing (late 2015), production over-the-counter mass produced traditional sidelock (flint or percussion cap) rifled long guns are mostly offered in .50 or .54 calibers. Fewer yet, some are also offered smaller calibers of .32 through .45 or larger calibers of .58 and above. Most of the calibers above .54 will be smoothbores and not rifles. Barrels are rifled with different twist rates. A slower twist rate of 1 turn in 60" (1:60) is very typical for a rifle firing patched round balls exclusively. A faster rate of twist such as 1:48 will allow both the acceptable loading and shooting of patched round balls or greased non-patched conical bullets. Some will have much faster twist rates and are suitable only for conical bullets. Smaller calibers require smaller lead balls of less mass weight, less volume powder charges, and will have less felt recoil. The .32 caliber is essentially about small game ("squirrel rifle") while the .45 caliber can be used for deer sized game and along with .40 caliber is a target favorite.

Smoothbore production long guns are harder to find, and are typically found in .54 through .78 calibers (28 through 10 gauges), and will typically cost more. These type of long guns were the most prevalent type of 18th century firearm because of their utilitarian versatility - they could fire either shot or ball, and had a more rapid rate of fire than a rifle, and thus were the de-facto long gun type of all the 18th century world's military. Their reasonable patched ball accuracy range varies by both shooter and gun, but 50 yards was considered the average against creature, or human.

Regardless of the barrel type or lock type, most long guns consist of a barrel, stock, lock, trigger(s), sight(s) and a ramrod.

Barrels can be of varying lengths, typically from 24" to 48", but can be shorter or longer as dictated by the gun's design or shooter's requirements. It's been said that a 24" barrel is optimum for accuracy, and longer barrels will yield a finer and more accurate sight radius.

Stocks are usually either full or half, typically made with a hardwood such as maple or walnut, but many other hardwoods can be, and are used.

While specific lock types may look alike and have the same function in mind, design geometry, materials, workmanship, timing and assembly can make a large difference in their performance.

There can be a simple single trigger, a single set trigger, or variations of a double set trigger where one trigger is pulled to "set" the other trigger to be pulled with just a light touch ("hair trigger").

Most sights are a simple blade up at the barrel's muzzle end, and for rifles and some (but not all) smoothbores, a "U" or "V" notched piece of metal inset on the barrel and lots closer to the lock. There are other speciality sights such as ladder peeps for the barrel or tang of special rifles. Longer barrels can offer a longer, finer, and more accurate sight radius.

The ramrod, typically of hardwood, is used for loading, fouling control and cleaning, and sits in tubes ("pipes") underneath the barrel.

ACCOUTREMENTS ...

ACCOUTREMENTS ...

Ammunition consists of black powder, lead balls (or lead shot, or greased conical bullets), ball patches or shot wads, flints or percussion caps.

It is Strongly Recommended to use real black powder and not "substitute black powder". The architecture of traditional muzzleloaders is built on using black powder charges, and thus black powder will allow more reliable ignition (particularly with flintlocks) and better overall performance. Black powder comes in a variety of granular sizes, with 1F the most coarse and 4F the finest. The most used types for the main powder charge are 2F (for .45 and above), 3f for all calibers, and 4F as the primer for flintlock pans. Flintlock pans can be primed with the the same type of powder used for the main charge, 2F or 3F. The notion of requiring a superfine 4F pan priming powder is a 20th century "invention". At best, the finest granularity of 18th and 19th century black powders was 2F. With a well tuned flintlock there is no need for 4F pan priming powder. Powder is kept in an animal horn or brass flask.

However, and at least initially with a first time production traditional flintlock, it might be best to start out using 4F for the pan powder, to insure good and reliable ignition, and consistently favorable outcomes.

Pure lead balls are typically cast .005" to .020" smaller in diameter than the long gun's bore, and are used with both rifles and smoothbores. This is to allow room for the patch. It's usually better to start off with a smaller ball, and go larger in diameter if necessary for improved accuracy. Lead shot (for use with smoothbores) and conical bullets (used with rifles) are the other forms of projectiles.

Patch material is for round balls and should be linen or 100% cotton. It's best to use a 1-1/2" wide strip of patch material rather than a precut round or square patch because a cut off patch will always be concentric to both the ball and barrel bore. It's usually better to start off with a number of different patch material thickness's - .005", .010", .015" - to see which one will work best with the ball diameter and barrel bore.

Wads of tag board or compressed fibers, in a typical thickness range of 1/16" to 1/2" are used for loading lead shot (shotgun). Conical lead bullets use no patches or wads, but have either grease grooves to accept a lubricant to reduce black powder fouling and improve accuracy, or are patched around the bullet's diameter with paper.

Flintlock ignition starts with a flint stone secured in the hammer (cock). One edge of the flint is squared to the frizzen and made sharp. When the flint strikes the frizzen it cuts off a tiny bit of sparking frizzen metal, which ignites the pan powder, sending radiant heat into the touch hole, which ignites the main powder charge. Caplock ignition starts with a percussion cap over the lock's nipple (cone). When the caplock's hammer strikes the percussion cap, it sends a flame down the nipple hole and ignites the main powder charge. The size of the hammer cock or nipple will dictate the size of the flint or percussion cap.

Black powder is considered an explosive and must be transported in a non-sparking container such as a powder horn or brass flask. A separate measure that is either fixed or adjustable for powder volume (not powder weight) is also typically made of horn or brass, and is used to both measure and load a precise powder charge into the gun's barrel.

The traditional ramrod is made of wood, typically hickory. It can be of all solid wood, or fitted at one end with a brass bushing that will accept a brass cleaning jag, or a brass cleaning brush, or a brass fouling scraper, or a patch worm for retrieving lost patches in the barrel, or a screw ball puller for unloading a gun barrel.

Other accessories include: a pick and/or pipe cleaner for cleaning the touch hole or nipple, a small brush (flintlock pan), percussion cap dispenser (cap lock nipple), patch knife, flintlock hammer cock screwdriver, caplock nipple wrench and clean out hole screwdriver, patch lube (tallow, water soluble oil, shortening, etc), fouling solvent (water, water plus water soluble oil, etc), a rag for general cleaning.

There is also a device called the "ball starter" or "short starter", which is used (sometimes with a hammer or mallet!) to force a tight fitting ball into the gun's muzzle, and then send it about 6" down the barrel before using the ramrod to home the patched ball. No such device has ever been found or mentioned for 18th and 19th century muzzleloaders.

Like using superfine 4F flintlock pan powder, the ball/short starter is a 20th century invention that was created for various reasons that include making it easy for muzzleloading beginners to load too tight fitting patched balls, or to make loading easier with fouled barrels, or in some manner for expected increased accuracy.

If a proper diameter ball, along with a proper thickness patch, are both chosen and tested to work well, there is no need for any "starter" rod. A well fitting patched round ball will push into the muzzle with a finger, and is easily pushed home to the powder charge with the ramrod. Likewise, proper fouling control will eliminate a tight fitting patched ball, and there is no absolute that a tightly patched ball is a requirement for muzzleloader accuracy. It's a sure bet that no 18th or 19th century muzzleloader would have loading difficulty because those weapons had to work reliably perfect every time as lives were at stake. Once again we need to look at and learn from the lessons of the past, from those who's lives depended on their firearms.

However, with all of the above stated and at least initially with a first time flintlock, it's probably a good thing to use a ball starter, to insure reliable and easy loading.

Research suggests that most 18th & 19th century muzzleloaders had coned muzzles. A slight to long taper was ground into the bore of the muzzle. This taper or funnel allowed the easier starting of patched balls or conical bullets. The coning could be as short as 1/8" to as long as 4", but most were on the shorter side. Production guns typically have no coned muzzles.

And, of course, a shooting bag to hold all the support goodies.

SHOOTING

SHOOTING - LOADING, FIRING, FOULING CONTROL ...

There are more than a few good and not-so-good methods of handling traditional muzzleloaders. Whilst seasoned old timers have their pet processes, listed and explained below are simple and effective procedures that have been long proven.

LOADING ...

The following pertains to loading a ball for a rifle or smoothbore traditional long gun. Loading lead shot (smoothbore) or conical bullet (rifle) will have some differences that will not be covered in this document. There are lots more than a few ways to load, shoot and care for a traditional muzzleloader. Forthwith are the authors' suggestions for a first time attempt at muzzleloading.

With any first time muzzleloading long gun, take its ramrod and drop it down the unloaded barrel, touching its end to the breech plug. Make a mark around the wooden ramrod at the muzzle with a marking pen and/or a knife scratch - this mark will allow checking for both an empty and loaded barrel.

Run a clean patch down the barrel to insure there is no residue. For caplocks, run a pick or pipe cleaner into the nipple to insure it's passageway is clean and open. For flintlocks, open the frizzen and put the hammer on half cock, run a pick or pipe cleaner into the touch hole to insure it's clean and open, wipe down the flint and pan and frizzen with a dry cleaning patch to remove any existing residue.

With a caplock long gun, keep the hammer down on top of the bare nipple (no cap installed!). With a flintlock long gun, and the hammer to half cock with the frizzen opened, insert a wooden round toothpick into the barrel touch hole to snugly plug it closed (it should be noted here, that our ancestors often used a feather from a small bird to plug the touch hole) - the alternative of NOT plugging the touch hole prior to loading powder down the tube is preferred by some folks.

Don both ear and and eye protection.

NOW is the time for FULL CONCENTRATION of the task at hand - creating a live ammunition weapon. There can be NO DISTRACTIONS. Stay focused on each part of the process and do not engage in any extraneous conversations or activities. Once started, the loading process should only be terminated by its completion, which renders a loaded lethal weapon.

Set the powder measure for the appropriate start load for your long gun and pour in black powder from the powder horn or flask. With either 2F or 3F black powder, a typical start charge volume is equal to the caliber, i.e. 50 grains of 2F or 3F for a .50 caliber long gun. When finished using, securely close the horn or flask and put it aside and away from the firing line. Set the long gun on its butt stock with its muzzle pointing towards the sky and slightly angled away from your face, pour the black powder charge (as measured by volume and not weight) into the gun's barrel. Thump the barrel or stock with the heel of your hand to settle the powder in the gun's barrel.

Place one end of a .010" thick linen patch strip (1-1/2" width by 6" to 20" long) that's been well lubricated with your saliva (or with tallow or vegetable shortening or water soluble oil or other similar muzzleloader lubricant) over the barrel muzzle, place a pure lead ball that's .010" smaller in diameter than the barrel's bore (i.e. - a .490" ball for a .50 caliber rifle) on top of the patch strip, with its sprue cut-off facing up. Push the ball flush to the barrel's muzzle with your thumb, or with a ball starter. Cut off the excess patch material with your sharp patch knife. Push the patched ball down the barrel with the ramrod or ball starter. Use the ramrod to seat the ball *firmly* on top of the powder. Push the patched ball, don't bang it repeatedly with the ramrod. Grasp the rod close to muzzle (4" to 6") and do the pushing in increments. This is where a tight patched ball can create issues that are easily solved with a looser patched ball. There can be no air space left between the powder and the patched ball.

With the lubricated patched round ball firmly on top of the powder inside the barrel, lower the rifle and point it down range. If this is your first time out with a muzzleloader, it's best to be seated at a bench and support the long gun's barrel on a sand bag or rolled up blanket or something similar. With a caplock long gun, pull back the hammer to half cock and place an appropriate size percussion cap (typically #11 or #10) on the nipple. With a flintlock long gun, pull back the hammer to half cock, open the frizzen, pull out the touch hole toothpick, open the powder horn or flask (or special 4F powder priming horn or flask) and sprinkle in a some grains of powder into the flintlock pan. The powder should be level with the pan top and fill it halfway, leaving 1/3 to 1/2 of the pan that is closest to the touch hole bare of any powder. Close the frizzen. Securely close the powder horn(s) or flask(s) and put such containers aside and way from the firing line.

FIRING ...

Pull the hammer back to full cock. With a finger OFF the trigger, take careful aim at a target placed not too far away, up to 25 yards distant - the top of the front blade is either on the center of the target face or slightly under it, and is framed left, right and top within the "U" or "V" of the rear sight. Make sure the butt stock is *firmly* against your shoulder. Place your non-trigger hand on the bottom rear of the stock to further brace the butt end when firing from a bench, or any other supported type of rest. If there are dual triggers, pull the rear set trigger and listen for the click setting of the forward trigger. Slowly move your trigger finger to either the single fire trigger or that front set fire trigger, take a few slow breaths, exhale the last breath slowly while still aiming and then touch the pad of your finger to the forward fire trigger and as the air slowly leaves your lungs, apply a continuous pressure to the fire trigger. If the gun goes "Bang!", success.

HOWEVER, if only the flintlock pan powder ignites, or only the percussion cap fires, HOLD THE GUN POINTED TOWARDS THE TARGET FOR AT LEAST A FULL MINUTE as there may still be an ember within the touch hole or nipple that could ignite the main charge. For a caplock - pull the hammer to half cock, remove spent cap and clean out the nipple hole. Insert a new percussion cap, and begin the aiming and firing process again. For a flintlock - pull the hammer to half cock, open the frizzen, thoroughly clean the flint, pan and frizzen. Inspect the flint - is the edge very sharp? If not, sharpen its edge or replace with a new sharpened flint. Run a pick and/or pipe cleaner into the touch hole and clean it well. Re-prime the pan, work just a few grains of powder into the touch hole, the rest of the pan powder needs to be 1/3 to 1/2 the pan's length away from the touch hole. Close the frizzen and begin the aiming and firing process again.

IF there is a second failure to fire, once again keep the gun's muzzle pointed down range for at least a full minute. The patched ball and powder must be removed from the barrel, and the problem of ignition failure must be determined. There are procedures and processes to safely accomplish these tasks, but they will not be covered within the scope of this document - seek on-site experienced assistance.

FOULING CONTROL ...

With the first round fired, and you wish to fire another round, let's address fouling control. Black powder ignition creates lots of residue in the barrel, as well as in a flintlock's touch hole, flint, pan and frizzen, and in a caplock's nipple. A cleaning patch that's moist with water or some black powder solvent is run down and out the barrel will remove most of this residue while keeping any existing residue soft, to make loading the next patched ball easier. Most production traditional muzzleloaders have patent breech plugs. This means there's a narrow diameter flue or tunnel that extends past the face of the breech plug and then doglegs towards the touch hole or nipple bolster. Since the cleaning jag is bore sized and larger than the flue, replace the jag with a .30 caliber brush to reach down into the flue and clean it out. Wipe down the flintlock's pan, flint and frizzen with a dry cleaning patch, and run a pick and/or pipe cleaner into its touch hole. Remove a caplock's spent cap, and with a dry cleaning patch, clean the outside of the nipple and hammer cup, then run a pick and/or pipe cleaner down the nipple hole. Reload.

MAINTENANCE

MAINTENANCE - CLEANING ...

After a day's shooting, it's important to clean the firearm as soon as possible because black powder is quite hygroscopic, attracts water, and promotes the rusting of steel and iron. Before packing up and leaving the range, run at least a few water or solvent wet patches down the barrel, then a few patches to dry, then a final patch that's sloppy wet with oil - leave the oily patch and ramrod down the barrel. At home, the barrel can be removed or remain on the stock. Run a few dry patches to remove any oil in the barrle. Plug the touch hole or nipple with a snug fitting round wooden toothpick. A small funnel comes in handy, or make one from paper, or don't use one at all, but stand the long gun on its butt stock and pour tepid tap water down the barrel and right up to the muzzle line. The water should NOT be hot. Allow that to sit there for 5 minutes. Lean the barrel or gun over so the touch hole or nipple faces the ground or a bucket and pull out the toothpick, allowing the water to drain out.

Run wet patches down the barrel, allowing any excess to shoot out the touch hole or nipple. Do this until the patches come out relatively clean, then run down a few dry patches, followed by a patch wet with most any gun oil (Breakfree, Hoppes, etc). Also, if the breech plug is a patent style and has a rear flue, replace the jag with a .30 caliber brush to clean it out as well. For a flintlock, remove the lock and wash down with water or solvent, dry off with cloth or cleaning patches, wipe over the internals with a cleaning patch that's moist with gun oil. Replace the lock. For a caplock, run drying pipe cleaners down the nipple, then one with a bit of oil on it, and wipe down the entire lock with an oily cloth. Wipe down any metal parts of the gun with an oily cloth as well. Wipe down the stock with either a clean damp, then dry, cloth or one moistened with a bit of Ballistol. The barrel may be left oiled as is, or an oil wet patch on the ramrod's jag can be sent and left down the barrel. Done.

SELECTION ...

Confused?

SELECTION ...

Confused? If you are a pilgrim with regards to traditional muzzleloaders, yes, it can get more than a bit confusing, it can be frustrating with so many choices. Take heart, let's try to make it all a bit easier. The authors will offer some opinions and suggestions.

There is NO VALUE in a muzzleloader that is of poor quality and unreliable performance. It's far more prudent to spend added dollars to secure a known good traditional muzzleloader than waste money on a firearm of dubious quality, durability and performance.

What to get? Lots will depend on your intent of use - hunting, target shooting, re-enactment, or casual shooting/plinking - and how much money you'd like to spend. It's really that simple, and maybe that difficult. Re-enactments will usually require period correct firearms. Most of the production line manufactured long guns have little to do with historical accuracy. For that type of firearm it may require seeking out a gunmaker and paying the price. But for all the rest, there are at least a few reasonably quality rifles (not smoothbores) in both flintlock and percussion to be had with budget price tags.

When you have decided on a traditional muzzleloader style of long gun (rifle or smoothbore, flintlock or percussion caplock), by all means it pays royally to seek out local one-on-one qualified assistance. If not, visit a traditional muzzleloading online forum (such as the BP Gang and TMA forum links at the top of this page) and seek out a qualified gunmaker, or assistance in buying a used gun on the classifieds.

Currently, mass produced traditional muzzleloading rifles are manufactured offshore. Some are quite good, others are not as good, some are borderline dangerous. There are more than a few onshore gunmakers and private builders of muzzleloaders, most are excellent. The cost difference between offshore and onshore muzzleloaders can be upwards of a thousand dollars or lots more. Then there are the used muzzleloaders, which can be a good cost savings, but as always, know exactly what you need and buyer beware.

A .50 caliber long rifle is typically considered complimentary for the hunting of deer and lesser sized game, whereas the .54 caliber is considered minimum for larger sized North American game, but this is simply a guideline of sorts. Both of these calibers are most common, and can be had in either lock type, flint or cap percussion, and various rates of barrel twist. Either of these calibers is fine for gun enthusiast range shooting at targets, and usually smaller calibers will exhibit less shoulder felt recoil.

If a quality traditional muzzleloader rifle purchase on a budget ($500) is the goal, whether flintlock or caplock, the ones made by Investarms (Italy) for the Lyman company have proven to be good, serviceable and accurate guns. In particular is their Trade Rifle that comes in either flintlock or caplock, .50 or .54 caliber, single trigger, and 28" full octagon blued barrel with a 1:48" rifling twist that will accommodate both balls and bullets. It can be had for well under $500 (as of 2015). These all have the keyed barrels and hooked breech plugs which allow easy barrel removal from the stock, and their locks are good performers. Their patent breech plugs can be removed (with the correct tools).

For typically more dollars, the Pedersoli company (Italy) offers quality rifles and smoothbores in a variety of styles and calibers, but expect to pay more than the Lyman company offerings.

At the lower end of the production line spectrum are the Spanish built traditional muzzleloaders offered by company vendors such as Traditions and CVA. Overall, these can usually be at least serviceable, safe flintlock and percussion rifles. Some will be under $400 but will not be the same quality as the Italian guns from Investarms (Lyman) or Pedersoli. Most, if not all of the Spanish rifles have breech plugs that can't be removed without destroying their barrel.

For exceptional quality and long term value, seek out a North American traditional muzzleloader gunmaker via the online forums and internet websites. While some of the gunmakers and gunsmiths ply their trade as their livilhood, there are also man qualified "hobbyist" gunmakers who produce some very fine long guns. All these guns will typically be in the $1000 to $3000 dollar (and more) price range, and will include any type of rifle or smoothbore, flintlock or caplock, with custom stocks, barrels and locks. Their offerings will also be as period and historically correct in terms of design, materials and build, as their customer requires - this is something that will not be found in a commercial production line traditional muzzleloader offering.

For the craftsman or adventurer, there are both budget and high quality kits of every type that can range from under $400 to over $2000.

Beyond this document, and for increased assistance with regards to all matters pertaining to traditional muzzleloaders, please visit The Black Powder Gang and The Traditional Muzzleloading Association website public forums and your questions will be answered by very knowledgeable folks who have been in the sport for decades.

Beyond this document, and for increased assistance with regards to all matters pertaining to traditional muzzleloaders, please visit The Black Powder Gang and The Traditional Muzzleloading Association website public forums and your questions will be answered by very knowledgeable folks who have been in the sport for decades.